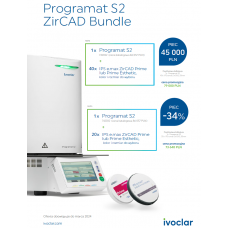

Programat S2 Zirconium sintering furnace PROMOTION

Promotion 1: Programat S2 + 40x IPS e.max ZirCAD Prime or Prime Esthetic (color and size to choose from) - Price PLN 79,000

Promotion 2: Programat S2 + 20 IPS e.max ZirCAD Prime or Prime Estethic (color and size to choose from) - Price PLN 73,640

Programat S2 is a compact oven designed for sintering caps, frameworks and full contour restorations made of IPS e.max ZirCAD or other zirconium oxide materials at temperatures up to 1600°C. Programat S2 is integrated into the Ivoclar workflow, ensuring optimally coordinated processing steps and consistently high-quality results.

Advantages:

Homogeneous heat distribution on objects allows for optimal sintering results at temperatures up to 1600 °C.

With a choice of three heating stages and two cooling stages, the sintering program offers a range of options for zirconium oxide materials.

Optimized cooling shelf provides more space and better cooling.

New, membrane-sealed keyboard with proven color touch display.

OSD display extended with the "cooling down" operating status.

Performance and reliability thanks to software optimization.

Warranty 2 years

Packaging:

- 1 piece.

Aidite - Pearls for sintering 500g

Cuvette beads for sintering zirconia works. High-quality.

Packaging:

- 500g

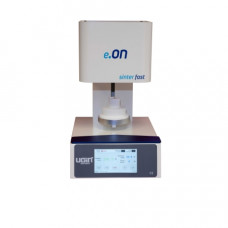

Ugin Litter box with lid for e.on sinter+/ base/fast

Cuvette with lid for zirconium sintering.

Technical data:

- Diameter 10 cm

- Height 3.5 cm

- Lid height 0.5 cm

Packaging:

- 1 piece

MICRO WAVES zirconium sintering furnace

NEW - Microwaves in zirconium oxide sintering.

Main advantages compared to conventional sintering furnaces:

- The total sintering time is approximately 4 hours

- Sintering time up to 1550 ºC: 110 min.

- Cooling to 300 ºC: 130 min.

Unlike conventional sintering units - where heat passes from the outside of the structure to the inside - in a microwave oven, heat is generated at all points in the structure, so the temperature is achieved more evenly. The resulting structure is cleaner, more durable and precise because there are no drafts during heating.

Zirconium is an excellent heat-resistant material. In a traditional oven, heating must be done gradually, observing levels, so that the temperature is evenly distributed throughout the prosthesis. Hence the long duration of sintering programs.

By using a microwave device, you will save on maintenance due to lower power, fewer components and smaller size.

- It does not contain delicate and expensive molybdenum silicate heating elements.

- Very low consumption: approximately 800/1100 W during the entire cycle.

- Possibility to carry out several production cycles on the same day.

- Production capacity increases rapidly.

- Extremely easy to use.

- Much smaller than standard ovens.

- It emits virtually no heat, which is appreciated in closed rooms in the summer.

- The stove is supplied with all necessary accessories for immediate operation

Technical data:

- Dimensions: 385 (W) x 440 (D) x 547 (H) mm.

- Weight: 31 kg.

- Power supply: AC 230 V, 50 Hz.

- Fuse: 15 A.

- Power: 2000 W

- Maximum temperature: 1550ºC.

Packaging:

- 1 piece

Chamber furnace for zirconium sintering NT ZIR-2 KXP4.1 R

HIGH TEMPERATURE CHAMBER FURNACE with KXP4.1 R controller.

The price includes delivery and installation in your laboratory:

NT ZIR-2 is a universal laboratory chamber furnace designed for precise, widely understood thermal treatment, including sintering of zirconia ceramics. The furnace uses high-quality insulating refractory materials and four spiral silicon carbide heating elements with a unique crystalline structure and long service life. The furnace is equipped with comprehensive automation which ensures the correct course of the process, protects the heaters against excessive heat load and ensures quick heating of the chamber.

Thanks to the special design of the chamber, high adjustment accuracy and controlled cooling, the NT ZIR-2 furnace enables the sintering process to be carried out in accordance with technological requirements. The sintered elements obtain optimal density and high mechanical strength parameters.

Advantages:

- Heating chamber capacity 1.9 dm3.

- Maximum temperature of continuous operation 1550°C.

- Four durable silicon carbide heating elements ensure even temperature distribution in the heating chamber.

- Double ventilated stainless steel housing for low external surface temperature.

- Multi-layer, energy-saving insulation of the chamber with a very low thermal conductivity coefficient.

- Door switch - disconnecting the power supply to the heaters and protecting the user against electric shock.

- Closed thermocouple with increased durability and high accuracy.

- Heater control system characterized by quiet operation,

- Fast heating rate (reaches 1400°C after 45 minutes).

- Overheating protection in case of thermocouple failure.

- Stove operating hours counter.

Technical data:

- Furnace chamber width 115mm, height 110mm, depth 150mm.

- External dimensions: width 515mm, height 353mm, depth 444mm.

- Weight 35 kg.

- temperature max. 1550 °C.

- Power supply 230V 50Hz.

- power max. 2700W

- Granular and fibrous insulation materials.

- Double vented stainless steel housing.

- Thermocouple temperature sensor in ceramic sheath PtRh10-Pt (type S).

KXP4.1 R controller parameters:

- Temperature setting range: 150°C - 1550°C.

- Temperature indication range: 20°C - 1560°C.

- Stop times: from 0 min to 9h 59min.

- Program. heating rate: from 1 to 65 [°C/min].

- Program. cooling rate: from -1 to -65 [°C/min].

- Temperature indication error: +/-3°C.

- Time accuracy: +/-0.4%.

- signaling energized chamber: yes

- signaling thermocouple opening: yes

- Machine. overshoot reduction: yes

- Memory back-up mechanism: battery-free.

Packaging:

- Bake with a controller.

- A cuvette with a lid for sintering (internal diameter x height: 90x35mm), and pearls (100g, size: 1mm).

DD phoeniX sintering oven cleaning powder 200g

DDphoeniX is a powder to help clean soiled sintering ovens. Regular use minimizes the problem of discoloration, thus extending the life of the heaters.

- Sintering - cleaning program - as recommended by the furnace manufacturer.

- Thorough cleaning (in case of problems with the color of works) 30--50 gr X 2 cleaning cycles.

- Regular cleaning (every 2 weeks) approx. 30gr x 1 cleaning cycle.

Precautions:

- When using the powder, use protective gloves and a mask to protect the eyes and mouth.

- Do not eat or drink while using the powder.

- Avoid breathing dust.

- Apply to the sinter tray at a distance and at moderate speed to avoid increased dusting.

Storage:

- Keep tightly closed in the original packaging.

- Store in a cool, dry place.

Packaging:

- 1pc/200g

Tabeo-1/M/Zirkon-100 zirconium sintering furnace

The Tabeo zirconium sintering furnace offers high-quality technology at a good price.

The TABEO series model variants are ideal for complementing smaller CAD/CAM systems or for expanding existing sintering furnaces.

Their respective capacities range from one sintering tray Ø= 100mm to three sintering trays Ø= 120mm. Your sintering program can be easily entered and saved in the program controller, which is adapted to the TABEO series. Pre-set service programs support you with simple maintenance and cleaning of heating systems.

TABEO offers the possibility of deciding on the use of heating systems with heating elements made of MoSi2 or SiC. Both systems are designed for conventional, long-term sintering. Heating elements made of molybdenum disilicide (MoSi2) provide a maximum furnace temperature of 1650°C. Thanks to predefined service programs, dirt on heating elements can be regenerated.

Due to their physical properties, heating elements made of silicon carbide (SiC) provide a maximum furnace temperature of 1550°C. SiC heating elements do not require regeneration using the service program.

Advantages:

- Sintering bowl ø 100mm.

- Capacity for a maximum of 20 individual crowns.

- 9 freely adjustable programs simplify operation.

- Regularly performing pre-set service programs can prevent possible discoloration of the restorations and extend the life of the heating elements and the heating chamber.

- Heating elements made of high-purity molybdenum disilicide

Technical Specifications:

- Dimensions (width x height x depth) 400 x 600 x 400 mm.

- Combustion chamber capacity 1 x sintering bowl ø 100 mm

- Maximum temperature 1650 °C.

- Weight 55 kg.

- Power supply 200 - 240 V (deviation ± 10%).

- Frequency 50/60 Hz.

- Maximum power consumption 1.3 kW.

- Energy consumption/cycle approx. 3.8 kWh.

Packaging:

- 1 piece

Zotion Sintering furnace F2

Zotion's new product, the F2 rapid zirconium oxide sintering furnace, is a good choice for your dental laboratory.

The F2 zirconium oxide sintering furnace is a high-tech equipment that ensures excellent sintering results and good forming quality. This equipment adopts the most advanced technology, high degree of automation and precise control system, which can ensure the best production efficiency and finished product quality. When in use, the F2 zirconium oxide sintering furnace ensures good stability and safety, and meets strict production standards and requirements.

Application:

- Zirconium sintering.

- Crystallization of glass ceramics.

- Glaze firing.

Advantages:

- No pollution thanks to the highest quality silicone molybdenum rods, they show longer service life than carbon rods.

- Maximum temperature rise speed 100℃/min.

- 3 sintering trays can be placed, this allows for sintering a large number of works.

Technical data:

Rated voltage - flow 220 VAC + 20%.

Rated power - 2500 W

Temperature control precision - ±1 °C.

Size - 42x30x60cm.

Net weight - 38.5 kg.

Rated temperature - 1650 °C.

Heating element - Silicone molybdenum rods.

Sintering chamber - 10x20cm (3-layer sintering tray).

Temperature control - Type B Digital control with double platinum-rhodium thermocouple.

Cooling - Zotion ultra-fast cooling technology.

Packaging:

- 1 piece

Aidite - Sinetring Box

A cuvette with a cover for sintering zirconium crowns and bridges, round, diameter 100 mm.

Packaging:

- 1 piece

UGIN e.ON sinter base sintering furnace

The e.ON zirconium sintering furnace is a compact, high-performance furnace. Equipped with 4 heating rods, it is a high-performance stove. Includes automatic door locking to avoid muff damage due to thermal shock. Technical Specifications:

- 7" high resolution color touch screen

- Maximum temperature 1600°C

- Maximum heating rate up to 40°C/minute

- 4 heating elements (rods) in MoSi2 (molybdenum disilicide)

- 1 sintering tray with lid and zircon pearls (capacity up to 20 pieces)

- 40 free programs with 40 possible steps for each program

- Visualization of graphic cycles

- 4 display languages: French, English, Italian, Spanish

- Muff size: 110mm x 110mm x 110mm

- External dimensions (height, width, depth): 540mm x 400mm x 450mm

- Weight: 58 kg

- Maximum power consumption: 1830 kW

- Supply voltage: 230V (50/60 Hz)

Ugin E.ON Sinter Base/Sinter+/Fast+ thermocouple

Thermocouple for the E.ON Sinter Base/Sinter+/Fast+ zirconium sintering furnace

Packaging:

- 1 piece

Ugin Zirconium sintering furnace e.ON Sinter Fast

The e.ON sinter fast zirconia sintering furnace from Ugin Dentaire is state-of-the-art equipment and unique effects, such as sintering individual works in just one hour.

40 programs increase the possibilities of long and very short sintering cycles.

Technical Specifications:

- High-resolution 7 inch (155mm x 87mm) color touch screen

- Cycle time: from one to several hours depending on the zirconium

- Maximum temperature 1750 ° C

- Temperature accuracy ± 1 ° C

- Maximum heating rate of 65 ° C / minute

- 1 MoSi2 (molybdenum disilicide) heating element

- Dual platinum / rhodium thermocouple component

- 1 sintering crucible (capacity up to 5 individual units)

- 40 programs with 40 possible stages for each program

- Graphical visualization of the cycle

- 4 display languages: French, English, Italian, Spanish

- Available space (height, diameter): 30mm x 35mm on the crucible

- External dimensions (height, width, depth): 550mm x 330mm x 430mm

- Weight: 29 kg

- Maximum power consumption: 2 kW

- Supply voltage: 230V (50/60 Hz)

e.ON sinter fast + zirconium sintering furnace

The e.ON sinter fast + zirconium sintering furnace from Ugin Dentaire presents state-of-the-art equipment and exceptional results, such as sintering in just one hour.

Technical Specifications:

- 7 inch (155 mm x 87 mm) high resolution color touch screen

- Maximum temperature 1730°C

- Operating temperature below 1650°C

- Temperature accuracy ± 1°C

- Cycle time: from one to several hours depending on the zirconia

- Maximum heating rate up to 65°C/minute

- 4 heating elements (rods) in MoSi2 (molybdenum disilicide)

- Dual thermocouple component Platinum/rhodium

- 2 sintering trays with cover and zirconium beads (capacity up to 40 units in conventional cycle and up to 20 units in short cycle)

- 40 programs with 40 possible steps for each program

- Visualization of graphic cycles

- 4 display languages: French, English, Italian, Spanish

- Muff size (height, diameter): 120mm x 110mm

- External dimensions (height, width, depth): 830mm x 420mm x 600mm

- Weight: 74 kg

- Maximum power consumption: 3 kW

- Supply voltage: 230V (50/60 Hz)

Zirconium synthesis furnaces - choose the best model for your prosthetic laboratory

Zirconium is a material with excellent aesthetic and mechanical properties, which is increasingly used in dental prosthetics. To obtain the maximum benefit from the use of zirconium, it is necessary to use an appropriate synthesizing furnace.

How does a zirconium sintering furnace work?

Zirconium sintering furnaces use a sintering process at high temperature (approx. 1550°C). During the sintering process, zirconium oxide particles combine with each other, creating a compact and durable structure.

What types of zirconium sintering furnaces are there?

Zirconium sintering furnaces can be divided into two main types:

- Conventional furnaces - use traditional heat sources, such as electric heaters or gas burners. Conventional ovens are less efficient than microwave ovens, but they are cheaper.

- Microwave ovens -- use radio waves to heat material. Microwave ovens are more efficient than conventional ovens and ensure a more even temperature distribution throughout the prosthetic work.

How to choose a zirconium sintering furnace?

When selecting a zirconium sintering furnace, the following factors should be considered:

- Type of material - zirconium sintering furnaces are designed to work with various types of zirconium oxide. You should choose a furnace that is suitable for the type of material from which prosthetic works will be made.

- Power - the power of the furnace determines how quickly it can reach the required temperature. Furnaces with higher power are more efficient and allow you to perform prosthetic work faster.

- Chamber size - the size of the furnace chamber determines how large prosthetic works can be sintered in it.

- Additional functions** - some zirconium sintering furnaces have additional functions, such as real-time temperature control or automatic cooling function.

Zirconium sintering furnaces in our offer

Our offer includes a wide selection of zirconium sintering furnaces, including both conventional and microwave furnaces. We offer furnaces from various manufacturers, at various prices and with various technical parameters.

Contact us for more information

If you need help choosing a zirconium sintering furnace, please contact us. Our experts will help you choose the model that best suits your needs.