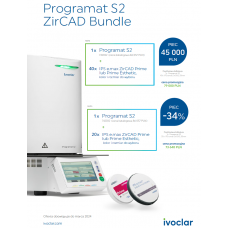

Programat S2 Zirconium sintering furnace PROMOTION

Promotion 1: Programat S2 + 40x IPS e.max ZirCAD Prime or Prime Esthetic (color and size to choose from) - Price PLN 79,000

Promotion 2: Programat S2 + 20 IPS e.max ZirCAD Prime or Prime Estethic (color and size to choose from) - Price PLN 73,640

Programat S2 is a compact oven designed for sintering caps, frameworks and full contour restorations made of IPS e.max ZirCAD or other zirconium oxide materials at temperatures up to 1600°C. Programat S2 is integrated into the Ivoclar workflow, ensuring optimally coordinated processing steps and consistently high-quality results.

Advantages:

Homogeneous heat distribution on objects allows for optimal sintering results at temperatures up to 1600 °C.

With a choice of three heating stages and two cooling stages, the sintering program offers a range of options for zirconium oxide materials.

Optimized cooling shelf provides more space and better cooling.

New, membrane-sealed keyboard with proven color touch display.

OSD display extended with the "cooling down" operating status.

Performance and reliability thanks to software optimization.

Warranty 2 years

Packaging:

- 1 piece.

MILLBOX software (versions: Clinic, Eco, Standard, Expert).

The most intuitive Dental CAM solution ever created.

MillBox is the first dental CAM solution developed to mill any part for a wide range of CAD/CAM materials. With a simple but powerful interface, the software makes nesting easy. Highly configurable and built to handle both standard operations and ad-hoc milling operations, MillBox includes predefined libraries but leaves you free to build your own strategies. Moreover, its special add-on module allows you to use both subtractive and additive techniques in one application. MillBox is a solution designed for dental laboratories, milling centers, machine builders and operators in the world of dentistry who need simple and reliable tools. It includes many features supported by artificial intelligence to guarantee you high performance in a short time and get the desired processes in a few simple steps.

MillBox is a dental CAM solution developed for milling all kinds of restorations from any material.

Featuring an easy-to-use user interface that is both innovative and attractive, MillBox simplifies nesting and toolpath creation.

An interface designed specifically for immediate use, with exciting new features that let you work even faster.

Specially designed for professionals who require simple and reliable tools. The MillBox gives you high performance in less time to get the job you want done in a few simple steps.

Designed for dental lab technicians, physicians, milling centers and anyone looking for a CAM that is constantly being updated and improved.

MillBox also offers specialized functions for high production environments, using artificial intelligence and system automation.

Technical properties:

REMOVAL OF ERRORS OF THE MESH FROM THE INSIDE OF THE BOLTED CROWNS

DETECTION OF EMERGENCY AREAS

AUTOMATIC SELECTION OF THE MOST OPTIMUM DISC FROM YOUR LIBRARY

OPTIMIZED LITHIUM DISILICATE MILLING

IMPLANT ANGLE DETECTION AND ITS MODIFICATION

MILLING WITH C-CLAMP

ANALYSIS OF THE THICKNESS OF YOUR RESTORATION

THE FITNESS OF CROWNS AND CONNECTORS

DETECTION, REMOVAL AND REPLACEMENT OF INTERFACES IN CONNECTORS

VISUALIZATION OF MULTILAYER MATERIALS DURING NESTING

DIRECT IMPORT OF STL FILES WITH AUTOMATIC RECOGNITION

Packaging:

- 1 piece

PoliDent PMMA X-RAY 98x12mm

PMMA X-RAY discs for milling diagnostic stents when planning implant treatment. Thanks to the homogeneous powder mix, it ensures the best visibility in X-ray imaging and prevents light scatter.

Characteristic:

- Vickers hardness: min 26 HV.

- Bending strength: min. 114 MPa.

- Flexibility modulus: min. 2771 MPa.

- Residual monomer: <1%.

Packaging:

- 1 piece

PoliDent PMMA X-RAY 98x16mm

PMMA X-RAY discs for milling diagnostic stents when planning implant treatment. Thanks to the homogeneous powder mix, it ensures the best visibility in X-ray imaging and prevents light scatter.

Characteristic:

- Vickers hardness: min 26 HV.

- Bending strength: min. 114 MPa.

- Flexibility modulus: min. 2771 MPa.

- Residual monomer: <1%.

Packaging:

- 1 piece

Zirconium Explore Esthetic 98x12mm

Zirconium Explore Esthetic new generation zircon, up to 5 layers of multilayer translucency. Thanks to the increased strength in the gingival area and increased translucency in the enamel area, it allows for a very wide range of applications, while maintaining high aesthetics of the restoration.

parameters:

- Strength after sintering 727 MPa - 1000 MPa.

- Translucency 47% - 48.8%

- Sintering temperature 1480 °C

Application:

- foundations.

- crowns.

- 3-point bridges.

- Bridge with overhang (not recommended for patients with bruxism).

Zirconium is a new line of materials based on zirconium oxide designed for use in cad/cam technology. Zirconium products are SFDA, ISO13485, CE and FDA certified. Thanks to the two-stage production process: axial pressing and "cold" isostatic pressing, zirconium zirconium discs are characterized by a homogeneous structure, which is a characteristic element of high-quality zirconia discs.

Packaging:

- 1 piece

Mesa - Magnum Solare disc Co-Cr 98.5x20mm Promotion

MAGNUM SOLARE 98.5x18mm - Co-Cr disc for milling ceramic-faced crowns and bridges.

Advantages:

- Lower hardness of 255 HV10, which facilitates milling and reduces wear of cutters.

- Pure oxidation.

- Thermal expansion coefficient suitable for most ceramic materials.

Composition in %:

- every 66

- Cr 27

- May 6

- Si,Mn 1

Technical data:

- Melting point 1307°C - 1417°C.

- Coefficient of thermal expansion - (25- 500 °C) 14.3 x10 - 6K- 1 - (25- 600 °C) 14.5 x 10- 6K- 1.

- Density - 8.4g/cm3.

- Vickers hardness 255 HV10.

- Percent elongation at break 11%.

- Unit yield strength - 395 Mpa.

- Modulus of elasticity 233 GPa.

Packaging:

- 1 piece

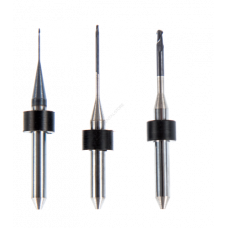

Zirconia milling drill bit type Zirkonzahn

Cutters adapted to Zirkonzahn milling machines.

- Head diameter 0.5mm,1.0mm,2.0mm.

- Handle diameter 3mm

- For milling in soft materials.

Package:

- 1 piece

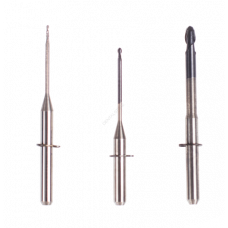

Drill for zirconia milling DLC type Yenadent

Cutters adapted to Yenadent milling machines.

- Head diameter 0.6mm,1.0mm,2.0mm.

- Handle diameter 4mm

- For milling in soft materials.

Packaging:

- 1 piece

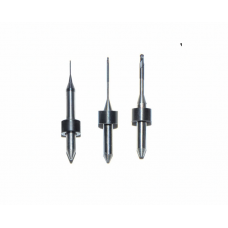

Wieland type DLC zirconia milling drill

Cutters adapted to Wieland milling machines.

- Head diameter 0.7mm, 1.0mm, 2.5mm

- Handle diameter 3mm

- For milling in soft materials.

Package:

- 1 piece

PMMA Up3D milling bit

Cutters adapted to Up3D milling machines.

- Head diameter 0.6mm, 1.0mm, 2.0mm.

- Handle diameter 4mm

- For milling PMMA

Packaging:

- 1 piece.

DLC milling drill bit type Amann Girrbach

Cutters adapted to AMANN GIRRBACH milling machines.

- Head diameter 0.6mm, 1.0mm, 2.5mm.

- Handle diameter 3mm.

- For milling in soft materials.

Packaging:

- 1 piece

Aidite - Pearls for sintering 500g

Cuvette beads for sintering zirconia works. High-quality.

Packaging:

- 500g

Cerec MC Care Liquid 250ml

MC Care Liquid is a preventive care and cleaning concentrate for use in the wet cleaning procedure of all Dentsply Sirona grinders and milling machines. In addition to its cleaning function, the fluid also has a maintenance function. It gives a pearl effect and has a slight descaling effect. If MC Care Liquid is used in every wet cleaning process, contamination of the processing chamber, hose system and nozzles is significantly reduced.

Packaging:

- 1 piece

Ugin Litter box with lid for e.on sinter+/ base/fast

Cuvette with lid for zirconium sintering.

Technical data:

- Diameter 10 cm

- Height 3.5 cm

- Lid height 0.5 cm

Packaging:

- 1 piece

EcoScan Dental H3D Premium 400ml

Anti-reflective spray for matting surfaces before scanning.

- Perfect for plaster, metal, wax and other materials.

Also available in the 4+1 free promotion:

Packaging:

- 400 ml

G-Cam Graphene-reinforced composite discs 98x20mm

Graphene-reinforced composite discs for milling in CAD/CAM systems. Thanks to graphene, G-CAM improves its strength in relation to its weight. The density of the material is low, making the prosthesis light.

Physical properties:

- Modulus of elasticity > 3200 MPa.

- Bending strength > 140 MPa.

- Hardness 88 Shore.

- Water absorption: 4 μg/mm3.

- Residual monomer <0.004%.

Advantages:

- Natural appearance of the restoration.

- The high glass transition temperature (Tg) prevents softening and distortion during use and cleaning of the restorations.

- Graphene improves the dimensional stability of polymers for dental use, which allows dental prostheses to maintain their shape for a very long time.

- Graphene also has high electrical conductivity to maintain a healthy oral mucosa.

- Graphene is waterproof and stable, does not allow plaque to accumulate, and, thanks to closed pores, dirt does not accumulate or discoloration occurs.

- The G-CAM disc is characterized by high abrasion resistance, which prevents excessive wear when cleaning dentures or eating food.

- The hardened material is neither irritating nor toxic to the patient. The G-CAM disc has undergone cytotoxicity and genetic tests conducted by the University of Alcalá and the Valencian Institute of Microbiology (IVAMI).

- In vitro cytotoxicity testing. ISO 10993-5:2009 standard.

- Reverse test for bacterial mutations. ISO 10993-3:2014 and OECD 471:1997.

- It is antiallergic.

- It has a bacteriostatic effect. Graphene does not allow bacteria or fungi to grow.

Application:

- The graphene composite disc can be used in all prosthetic restorations.

- Crowns.

- 3-point bridges.

- Bridges on > 2 implants

- Outlays.

- Veneers.

- Complete dentures.

- Temporary restorations.

Packaging:

- 1 piece

Scanspray extra fine 200 ml

Due to its micro-fine, homogeneous structure, Renfert-Scanspray extra fine can be applied very thinly. Increased adhesion, especially on polished ceramics/metals and reflective surfaces.

Renfert catalog number 17312000

Packaging:

- 1 piece

G-Cam Multi composite discs reinforced with Graphene 98x20mm

Graphene-reinforced composite discs for milling in CAD/CAM systems. Thanks to graphene, G-CAM improves its strength in relation to its weight. The density of the material is low, making the prosthesis light.

Physical properties:

- Modulus of elasticity > 3200 MPa.

- Bending strength > 140 MPa.

- Hardness 88 Shore.

- Water absorption: 4 μg/mm3.

- Residual monomer <0.004%.

Advantages:

- Natural appearance of the restoration.

- The high glass transition temperature (Tg) prevents softening and distortion during use and cleaning of the restorations.

- Graphene improves the dimensional stability of polymers for dental use, which allows dental prostheses to maintain their shape for a very long time.

- Graphene also has high electrical conductivity to maintain a healthy oral mucosa.

- Graphene is waterproof and stable, does not allow plaque to accumulate, and, thanks to closed pores, dirt does not accumulate or discoloration occurs.

- The G-CAM disc is characterized by high abrasion resistance, which prevents excessive wear when cleaning dentures or eating food.

- The hardened material is neither irritating nor toxic to the patient. The G-CAM disc has undergone cytotoxicity and genetic tests conducted by the University of Alcalá and the Valencian Institute of Microbiology (IVAMI).

- In vitro cytotoxicity testing. ISO 10993-5:2009 standard.

- Reverse test for bacterial mutations. ISO 10993-3:2014 and OECD 471:1997.

- It is antiallergic.

- It has a bacteriostatic effect. Graphene does not allow bacteria or fungi to grow.

Application:

- The graphene composite disc can be used in all prosthetic restorations.

- Crowns.

- 3-point bridges.

- Bridges on > 2 implants

- Outlays.

- Veneers.

- Complete dentures.

- Temporary restorations.

Packaging:

- 1 piece

MICRO WAVES zirconium sintering furnace

NEW - Microwaves in zirconium oxide sintering.

Main advantages compared to conventional sintering furnaces:

- The total sintering time is approximately 4 hours

- Sintering time up to 1550 ºC: 110 min.

- Cooling to 300 ºC: 130 min.

Unlike conventional sintering units - where heat passes from the outside of the structure to the inside - in a microwave oven, heat is generated at all points in the structure, so the temperature is achieved more evenly. The resulting structure is cleaner, more durable and precise because there are no drafts during heating.

Zirconium is an excellent heat-resistant material. In a traditional oven, heating must be done gradually, observing levels, so that the temperature is evenly distributed throughout the prosthesis. Hence the long duration of sintering programs.

By using a microwave device, you will save on maintenance due to lower power, fewer components and smaller size.

- It does not contain delicate and expensive molybdenum silicate heating elements.

- Very low consumption: approximately 800/1100 W during the entire cycle.

- Possibility to carry out several production cycles on the same day.

- Production capacity increases rapidly.

- Extremely easy to use.

- Much smaller than standard ovens.

- It emits virtually no heat, which is appreciated in closed rooms in the summer.

- The stove is supplied with all necessary accessories for immediate operation

Technical data:

- Dimensions: 385 (W) x 440 (D) x 547 (H) mm.

- Weight: 31 kg.

- Power supply: AC 230 V, 50 Hz.

- Fuse: 15 A.

- Power: 2000 W

- Maximum temperature: 1550ºC.

Packaging:

- 1 piece

DC milling drill bit type VHF - NEW!!!

Cutters adapted to VHF milling machines.

- Made of an optimal combination of steel alloy and carbide with a diamond coating.

- Thanks to the unusually long service life, 1 drill can cut up to 500 crowns.

- Head diameter 0.3mm, 0.6mm, 1.0mm, 2.0mm.

- Handle diameter 3mm

- For milling in soft materials (Zirconia)

Package:

- 1 piece

Chamber furnace for zirconium sintering NT ZIR-2 KXP4.1 R

HIGH TEMPERATURE CHAMBER FURNACE with KXP4.1 R controller.

The price includes delivery and installation in your laboratory:

NT ZIR-2 is a universal laboratory chamber furnace designed for precise, widely understood thermal treatment, including sintering of zirconia ceramics. The furnace uses high-quality insulating refractory materials and four spiral silicon carbide heating elements with a unique crystalline structure and long service life. The furnace is equipped with comprehensive automation which ensures the correct course of the process, protects the heaters against excessive heat load and ensures quick heating of the chamber.

Thanks to the special design of the chamber, high adjustment accuracy and controlled cooling, the NT ZIR-2 furnace enables the sintering process to be carried out in accordance with technological requirements. The sintered elements obtain optimal density and high mechanical strength parameters.

Advantages:

- Heating chamber capacity 1.9 dm3.

- Maximum temperature of continuous operation 1550°C.

- Four durable silicon carbide heating elements ensure even temperature distribution in the heating chamber.

- Double ventilated stainless steel housing for low external surface temperature.

- Multi-layer, energy-saving insulation of the chamber with a very low thermal conductivity coefficient.

- Door switch - disconnecting the power supply to the heaters and protecting the user against electric shock.

- Closed thermocouple with increased durability and high accuracy.

- Heater control system characterized by quiet operation,

- Fast heating rate (reaches 1400°C after 45 minutes).

- Overheating protection in case of thermocouple failure.

- Stove operating hours counter.

Technical data:

- Furnace chamber width 115mm, height 110mm, depth 150mm.

- External dimensions: width 515mm, height 353mm, depth 444mm.

- Weight 35 kg.

- temperature max. 1550 °C.

- Power supply 230V 50Hz.

- power max. 2700W

- Granular and fibrous insulation materials.

- Double vented stainless steel housing.

- Thermocouple temperature sensor in ceramic sheath PtRh10-Pt (type S).

KXP4.1 R controller parameters:

- Temperature setting range: 150°C - 1550°C.

- Temperature indication range: 20°C - 1560°C.

- Stop times: from 0 min to 9h 59min.

- Program. heating rate: from 1 to 65 [°C/min].

- Program. cooling rate: from -1 to -65 [°C/min].

- Temperature indication error: +/-3°C.

- Time accuracy: +/-0.4%.

- signaling energized chamber: yes

- signaling thermocouple opening: yes

- Machine. overshoot reduction: yes

- Memory back-up mechanism: battery-free.

Packaging:

- Bake with a controller.

- A cuvette with a lid for sintering (internal diameter x height: 90x35mm), and pearls (100g, size: 1mm).

Ambarino 98x15mm - ceramics 70% composite 30%

Ambarino - a highly aesthetic material, a mixture of 70% ceramics and 30% composite. The most flexible ceramic material available on the market. Elasticity allows it to absorb the force of opposing teeth during chewing, which minimizes cracks and mechanical damage to the restoration.

Application:

- Permanent and temporary prosthetic restorations (crowns, bridges, inlays, onlays, veneers).

- Perfect for full anatomical work in the anterior and lateral sections.

Packaging:

- 1 piece.

Zirconium Explore Hybrid 98x30mm + Gingiva 20ml

Discover tooth restoration with UPCERA Explore Hybrid.

Explore Hybrid disc with a diameter of 30 mm, designed to smoothly adapt to the natural structure of the teeth. Say goodbye to the limitations of typical gradient discs with Explore Hybrid. Effortlessly achieve light to dark pink gums. A solid base ensures durability and transparency. Thanks to Explore Hybrid, you will never lose the color of your gums again.

Sintering parameters:

- 1150°C 4°C/min 30 min

- 1300°C 2°C/min -1480°C 4°C/min 150min

- 800°C -8°C/min

- Open at 500°C

Packaging:

- 1 pc + Gingiva 20ml

Up3d P42 ceramic milling machine - NEW!!!

P42 milling machine High standards High quality.

COMMERCIAL INFORMATION/CONTACT:

Mikran.pl ul. Wojskowa 3/L4 60-792 Poznań sklep@mikran.pl, www.mikran.pl Possibility of free presentation of the milling machine in your workshop/office.

Call us: +48 600 128 010 or +48 530 596 166.

Advantages:

- Grinding with pure water, you don't need another grinding fluid, take care of the material, say goodbye to cumbersome waste disposal.

- Possibility of grinding many materials (glass ceramics, hybrid, composite, titanium).

- Milling an ultra-thin 0.2 mm veneer.

- P 42 capable of milling to remove undercuts by tilting the A axis by #20° to ensure each restoration is perfectly fitted.

- Simple and easy to use, connected to the UPLink platform for remote monitoring, intelligent and highly efficient.

- CAM software UPCAM (optional Millbox).

Application:

- Veneers.

- Iinlay, onlay.

- Crowns.

- Telescopic crowns.

- Bridges.

- Connectors.

Technical data:

- Weight 80 kg.

- Dimensions 571x449x585 (mm).

- Tool magazine 6 pieces.

- Spindle power 550 W.

- Number of controlled axes 4.

- Stepper motor axis drive.

- Wet working Yes.

- Spindle speed 60,0000 rpm.

- Handle diameter 4 mm.

- CAD/CAM material storage Manual.

- The LED bar displays the machine status.

- Built-in camera to monitor the grinding status.

Packaging:

- 1 piece.

DD phoeniX sintering oven cleaning powder 200g

DDphoeniX is a powder to help clean soiled sintering ovens. Regular use minimizes the problem of discoloration, thus extending the life of the heaters.

- Sintering - cleaning program - as recommended by the furnace manufacturer.

- Thorough cleaning (in case of problems with the color of works) 30--50 gr X 2 cleaning cycles.

- Regular cleaning (every 2 weeks) approx. 30gr x 1 cleaning cycle.

Precautions:

- When using the powder, use protective gloves and a mask to protect the eyes and mouth.

- Do not eat or drink while using the powder.

- Avoid breathing dust.

- Apply to the sinter tray at a distance and at moderate speed to avoid increased dusting.

Storage:

- Keep tightly closed in the original packaging.

- Store in a cool, dry place.

Packaging:

- 1pc/200g

VOCO Grandio disc - multicolor Ø 98mmx15mm

Nanoceramic hybrid CAD/CAM discs, which are a multicolored version of Grandio nanoceramic discs. Thanks to the properties of the material, the three interpenetrating color layers of the Grandio multicolor disc make the restoration look very lively. The Invisible Layer Technology used in the discs imitates the natural color gradient of the tooth, from the incisal edge to the tooth neck, providing restorations with excellent aesthetics.

Indications:

- Crowns, inlays, onlays, veneers.

- Crowns supported on implants.

Advantages:

- Excellent aesthetic restorations with just three layers.

- The special composition of the material provides restorations with a color gradient that faithfully imitates natural teeth.

- The highest filler content (86% by weight) provides restorations with maximum mechanical strength and lowest abrasion.

- Easy to polish and repair.

Packaging:

- 1 piece

VOCO Structur CAD - disc Ø 98mmx20mm

CAD/CAM composite for temporaries.

Indications:

- Temporary bridges with up to two spans.

- Temporary crowns with abutment.

- Temporary crowns.

Advantages:

- Quickly and efficiently fabricate precise CAD/CAM temporaries.

- The highest quality and aesthetics ensuring long-term, safe and comfortable use - the product is perfect for long-term and semi-permanent temporary restorations.

- Exceptional margin stability.

- Easy polishing and intra- and extra-oral individualisation.

- Use without MMA primer.

Packaging:

- 1 piece

VOCO Structur CAD - universal block 5 x 40L

CAD/CAM composite for temporaries.

Indications:

- Temporary bridges with up to two spans.

- Temporary crowns with abutment.

- Temporary crowns.

Advantages:

- Quickly and efficiently fabricate precise CAD/CAM temporaries.

- The highest quality and aesthetics ensuring long-term, safe and comfortable use - the product is perfect for long-term and semi-permanent temporary restorations.

- Exceptional margin stability.

- Easy polishing and intra- and extra-oral individualisation.

- Use without MMA primer.

Packaging:

- 5pc/1pack

Helling 3D Anti-Glare Spray 400ml

Anti-glare spray for matting the surface before scanning.

Packaging:

- 400 ml

Outlet Zirconium ST Color A3.5 AG 89-71-18 mm short expiry date

Zirconium ST Color A3.5 AG 89-71-18 mm - short expiry date.

Packaging:

- 1 piece

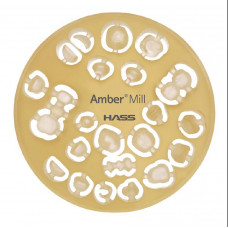

Amber Mill Disc 98x14mm

Amber Mill is the first lithium disilicate glass-ceramic material with adjustable translucency through temperature and crystallization time (HT/MT/LT/MO).

It is characterized by unrivaled mechanical properties, easy processing and high aesthetic values.

Strength after crystallization 450MPa.

Translucency is dependent on crystallization time.

Packaging:

- 1 piece.

Exocad Basic course combined with a scanning demonstration at the client's workshop

Introduction to digital prosthetics with Exocade.

A one-day course in the client's workshop for people starting or thinking about starting work in the CAD/CAM environment. The training is intended for dental technicians and prosthodontists.

During the course you will learn:

THEORY:

- Digital workflow – scanning, design, production.

- Benefits of introducing digitalization into your laboratory.

- Exocad software capabilities.

- Q&A

PRACTICE:

- Introduction to digital prosthetics - demonstration of scanning on the Up3D prosthetic scanner.

- Discussion of the Exocad interface and creation of a prosthetic patient card.

- Designing a crown in three options (Offset coping, Coping, Anatomic crown) and a structure for a 3-unit veneered bridge.

- Analysis of all design stages

- Discussion of useful functions of the Expert mode on the example of a designed bridge.

After completing the course, each participant receives a certificate of participation;

Registration/registration:

- Lic.tech.dent Kamil Wolniewicz, certified Exocad trainer. kamil.wolniewicz@mikran.com tel. 530596166

Milling drill type Imes Icore for glass ceramics

Cutter designed for processing glass ceramics with a diameter of 0.6mm, 1mm, 2.5mm. Dedicated to imes-icore type milling machines with a 3 mm diameter chuck. With diamond coating for longer tool life.

Package:

- 1 piece

EcoScan Spray scanning spray 200ml

A powder-based spray that improves the quality of model scanning by CAD/CAM scanners.

Instruction:

When using, hold the package vertically, use from a distance of 4-6 cm. Once you have finished scanning, you can clean the model with hot steam.

CFC-free - non-flammable.

**Packaging: **

- 200 ml

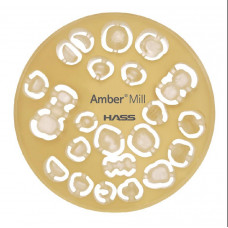

Amber Mill Disc 98x16mm

Amber Mill is the first lithium disilicate glass-ceramic material with adjustable translucency through temperature and crystallization time (HT/MT/LT/MO).

It is characterized by unrivaled mechanical properties, easy processing and high aesthetic values.

Strength after crystallization 450MPa

Translucency is dependent on crystallization time.

Packaging:

- 1 piece.

Silent Power CAM TC extractor for milling machines

Efficient and affordable CAM extractor with collector motor, especially suitable for medium and large CAM systems.

Renfert catalog number 29380000

Advantages:

- Consistently full suction power thanks to automatic filter cleaning.

- Reliable production process thanks to innovative engine technology (3x longer service life compared to conventional collector engines).

- High suction efficiency up to 3980 l/min.

- Bi-directional communication between the suction unit and CAM equipment thanks to the PLC interface.

- Bagless fine filtering technology.

- Easy motor replacement in minutes.

- Work in quiet conditions thanks to low noise level max. 54.3 dB(A).

- 36-month warranty.

Technical data:

- Permissible mains voltage - 220–240 V.

- Permissible network frequency - 50/60 Hz.

- Energy consumption - 850 W (230 V).

- Volume flow - (max.) 3980 l/min.

- Max depression - 281 hPa.

- Engine technology - Manifold.

- Filter technology - bagless.

- Filter quality - Class M according to EN 60335-2-69.

- CAM interface - RJ45 socket.

- Mains input fuse - 2 x 15 A(T).

- Number of suction hoses - 1.

- Sound pressure level (LpA) - 54.3dB(A).

- Weight ~22 kg.

- Dimensions (width x height x depth) - 275x535x540mm.

- Ø internal suction ports - 45mm.

- Ø external suction connections - 50mm.

- Dust container capacity ~7 l.

Packaging:

- SILENT powerCAM TC.

- Quick start guide.

- Quick information card.

- 3 waste bags (1 piece placed in the dust container).

- 2 m suction hose with 2 end silencers.

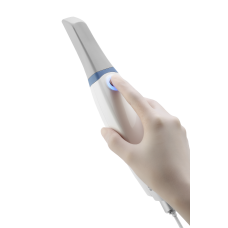

Runyes 3DS V3 intraoral scanner + scanner table FREE!

Runyes 3DS 3.0 from Runyes Medical is one of the newest intraoral scanners introduced to the market.

Advantages:

- CE, FDA, ISO13485, GOST, INMETRO, ANVISA and registration certificates of other 12 countries.

- True 3D color - The latest image rendering technology makes color reproduction realistic, which is convenient for doctor-patient communication.

- The Al function built into the software not only removes any captured soft tissue artifacts, but completely ignores the tongue and cheeks.

- Comfortable and light handle.

- Protection against accidental unplugging of the power cable.

- Innovative mirror heating system, without the use of air.

- Can be sterilized in an autoclave (up to 100 times per tip).

- Open system (.STL, .OBJ, .PLY files).

- Service in Polish.

- 2 tips included (mini 12mm/12mm, standard 15mm/15mm).

- Oral health report.

- Real-time overview.

- Complete ecosystem with 3shape, exocad, dental wings, BlueSkyBio, ASIGA systems,

- Cloud sharing.

- Unique features (metal scanning, margin line drawing, model builder)

Technical Specifications:

- Handle dimensions (L x W x H) 240mm X 49.5mmX30.5mm.

- Handle weight 210g.

- Standard tip size 79mm x 19.7mm x 15.8mm.

- Mini tip size 80mm x 16mm x 11mm.

- Scanning area (standard) 15mmX15mm.

- Scanning area (Mini) 12mmX12mm.

- Depth of field; 15mm.

- Sterilization in autoclave up to 100 times, at 121°C 16 min, at 134° 4 min.

- Accuracy; crown

- Scanning speed; single arc 30 s, full arc with occlusion 90 s.

- No calibration.

- STL, OBJ, PLY output.

- USB3.0 connectivity.

- Operating languages; Chinese, English, French, Spanish, Russian, Portuguese, Italian, Greek, Polish, Romanian, Japanese and Korean.

Packaging:

- 1 piece

Mesa - ERGAL Test disk 98.5x20mm

New ERGAL discs for testing and fitting work. It is an alloy (aluminum with zinc, magnesium and copper and trace additives of other metals).

Due to its excellent milling performance, this alloy is well suited for the production of test pieces. In addition, it guarantees extremely high precision and, at the same time, extreme ease of execution.

Package:

- 1 piece

Zirconium HT White 98x10mm

Zirconium is a new line of materials based on zirconium oxide designed for use in cad/cam technology. Zirconium products are SFDA, ISO13485, CE and FDA certified. Thanks to the two-stage production process: axial pressing and "cold" isostatic pressing, zirconium zirconium discs are characterized by a homogeneous structure, which is a characteristic element of high-quality zirconia discs.

HT - High translucent

Characteristics:

- Recommended for foundations.

- Very high strength.

Destiny:

- Cap.

- Bridges.

- 3-4 point bridge.

- Bridge with overhang ((not recommended for patients with bruxism).

- Inlay bridge (not recommended for patients with bruxism).

- Maryland bridge (not recommended for patients with bruxism).

- Telescopic crown.

- Individual connectors.

Chemical composition:

- ZrO2 + HfO2 + Y2O3 - >99%

- Y2O3 - 4.5%~6%

- HfO2 - <5%

- Al2O3 - <0.5%

- Other oxides - <0.5%

Physical properties:

Density before sintering - 3.1+0.5g/cm3

Density after sintering - 6.08+0.01g/cm3

CTE (25- 500°C) 10.05+1.0×10- 6K- 1

Strength after sintering - 1300 Mpa

Percentage of monoclinic accelerated aging (%) - <15%

Average transparency - 39%

Cytotoxicity test - 0

Radioactivity - <0.1Bq/g

Sintering temperature - 1530°C

Packaging:

- 1 piece

Tabeo-1/M/Zirkon-100 zirconium sintering furnace

The Tabeo zirconium sintering furnace offers high-quality technology at a good price.

The TABEO series model variants are ideal for complementing smaller CAD/CAM systems or for expanding existing sintering furnaces.

Their respective capacities range from one sintering tray Ø= 100mm to three sintering trays Ø= 120mm. Your sintering program can be easily entered and saved in the program controller, which is adapted to the TABEO series. Pre-set service programs support you with simple maintenance and cleaning of heating systems.

TABEO offers the possibility of deciding on the use of heating systems with heating elements made of MoSi2 or SiC. Both systems are designed for conventional, long-term sintering. Heating elements made of molybdenum disilicide (MoSi2) provide a maximum furnace temperature of 1650°C. Thanks to predefined service programs, dirt on heating elements can be regenerated.

Due to their physical properties, heating elements made of silicon carbide (SiC) provide a maximum furnace temperature of 1550°C. SiC heating elements do not require regeneration using the service program.

Advantages:

- Sintering bowl ø 100mm.

- Capacity for a maximum of 20 individual crowns.

- 9 freely adjustable programs simplify operation.

- Regularly performing pre-set service programs can prevent possible discoloration of the restorations and extend the life of the heating elements and the heating chamber.

- Heating elements made of high-purity molybdenum disilicide

Technical Specifications:

- Dimensions (width x height x depth) 400 x 600 x 400 mm.

- Combustion chamber capacity 1 x sintering bowl ø 100 mm

- Maximum temperature 1650 °C.

- Weight 55 kg.

- Power supply 200 - 240 V (deviation ± 10%).

- Frequency 50/60 Hz.

- Maximum power consumption 1.3 kW.

- Energy consumption/cycle approx. 3.8 kWh.

Packaging:

- 1 piece

HinriMill E4 milling machine

Digitize your practice with HinriMill e4! You and your patients will benefit from dental restorations in one treatment session. The new HinriMill e4 makes it easy to start fabricating prosthetic restorations at the chairside, giving you maximum freedom. Connect HinriMill e4 to your preferred intraoral scanner, any CAD software and materials appropriate to your patient's case. HinriMill e4 is the heart of your work and performs the perfect restoration for you. With the included CAM software you can get started right away!

Due to its low weight of only 28 kg and the complete absence of compressed air, the HinriMill e4 offers maximum flexibility in positioning. Place HinriMill e4 anywhere. As the motto goes: unpack, turn on, start milling!

Discover AITROOL, a breakthrough technology that gives you incredible freedom and flexibility when processing details. Thanks to Airtoll, our machines no longer require an external compressed air connection or a built-in compressor. Instead, the AIRTOOL turbine blades produce a powerful air flow that protects the workpiece from chips and dust during the milling process. This not only provides a better working environment, but also increases machining efficiency. Join the progress.

Fast and precise:

- Spindle 800 W 60,000 rpm.

- Repetition accuracy 3 μm.

- No compressed air required thanks to the patent-pending AIRTOOL.

- Solid welded aluminum construction.

- 100% developed and manufactured in Germany.

- DENTALCAM software with an open interface to CAD software and materials.

- Any intraoral scanners can be used.

- Mills almost all blocks up to 45 mm long from many manufacturers (glass ceramics, composites, zirconium and plastics)

Advantages:

- Four-axis milling machine.

- 7 tools.

- 1 block.

- Wet and dry milling.

Packaging:

- 1 piece

DC milling drill bit type Up3D Flat 1.0mm

Cutters adapted to Up3D milling machines:

- Made of an optimal combination of steel alloy and carbide with a diamond coating.

- Thanks to the unusually long service life, 1 drill can mill up to 500 crowns.

- Head diameter 1.0mm.

- flat

- Handle diameter 4mm

- For milling in soft materials. (Zirconium)

Package:

- 1 piece.

Mesa - ERGAL Test disk 98.5x16mm

New ERGAL discs for testing and fitting work. It is an alloy (aluminum with zinc, magnesium and copper and trace additives of other metals).

Due to its excellent milling performance, this alloy is well suited for the production of test pieces. In addition, it guarantees extremely high precision and, at the same time, extreme ease of execution.

Package:

- 1 piece

Amber Mill C12 / 5pcs PROMOTION

Amber Mill is the first lithium disilicate glass-ceramic with the ability to regulate translucency by temperature and crystallization time (HT / MT / LT / MO).

Benefits:

It is characterized by unrivaled mechanical properties, easy processing and high aesthetic values.

Strength after crystallization 450MPa

Translucency is dependent on the time of crystallization.

Attention:

- For processing and polishing, we recommend the Diadur / Diapro stone and rubber set, code mikran 2251

Package:

- 5 pcs / 1 box

Telescan - a preparation that improves contrast when scanning CAD/CAM

A preparation that prepares the surface of the model for CAD/CAM scanning.

Characteristics:

- Significantly improves the contrast,

- It has an anti-reflective component.

Application:

Spray the model from a distance of 10-15 cm so that a thin layer of the preparation is formed.

Shake before use.

Packaging:

- 75 ml

Ambarino 98x20mm - ceramic 70% composite 30%

Ambarino highly aesthetic material, a mixture of 70% ceramics and 30% composite. The most flexible ceramic material on the market. The flexibility allows it to absorb the force of the opposing teeth during chewing, which minimizes cracks and mechanical damage to the restoration.

Application:

- Permanent and temporary prosthetic restorations (crowns, bridges, inlays, onlays, veneers)

- Ideal for full-contour work in the anterior and posterior region.

Packaging:

- 1 piece.

Zirconium milling wax gray 98x14mm Promotion

Synthetic milling wax, very hard, non-sticky. It guarantees high precision of work. Size 98x14mm

Package:

- 1 piece

Materials and device for CAD/CAM technology used in prosthetics.

Our offer includes a wide selection of materials and devices for use in CAD/CAM technology. Probably the most popular material for CAM milling in prosthetics are zirconium oxide discs, commonly called zirconium discs or milling blocks . Zirconium oxide is a ceramic material, without the addition of glass, made of very small grains. The quality of the zirconium oxide powder grains determines whether the zirconium block will fulfill its purpose.

The advantages and properties of zirconium discs are mainly high crushing resistance, crack resistance, fine-grained structure, biocompatibility and biocompatibility. Additionally, it guarantees high tightness of the crown and precise adherence to natural teeth. It does not cause any allergies in patients. Thanks to their abrasion resistance, zirconium teeth can be used for a very long time, combining quality with a very high aesthetic effect.

We also offer PMMA blocks . PMMA is a popular polymethyl methacrylate material. It is a resin that is perfect for making crowns and bridges for temporary restorations. The great advantage of the material is its biodegradability, thanks to which it burns without residue. Additionally, PMMA has high bending strength >80MPa, natural fluorescence and high transparency. It is very easy to mill, with minimal wear on the cutters. Its cost is approximately PLN 80 for a disc in any Vita color and regardless of height, from which up to 30 points can be cut - this makes it one of the favorite materials of prosthetists.

Acrylic resin has great potential, which is why it is constantly being improved. PMMA multilayer is now standard, which ensures smoother transitions of layers of a given color.

Our offer includes, among others:

- Milling blocks and discs made of Zirconium zirconium oxide

- Bond for zirconium,

- Hyramic,

- IPS e.max ZirCAD,

- Ceramic-composite discs,

- Metal milling discs,

- PEEK discs,

- PMMA discs,

- PMMA discs for casting,

- Lithium disilicate discs,

- Plaster discs,

- Wax discs

- Processing materials

- Software

- Scanning preparations

- Liquids for dyeing zirconium

- Devices - prosthetic milling machines and scanners

- Drills